Quantum Controls stands at the forefront of electronic manufacturing excellence, offering comprehensive turnkey solutions for a wide range of industries.

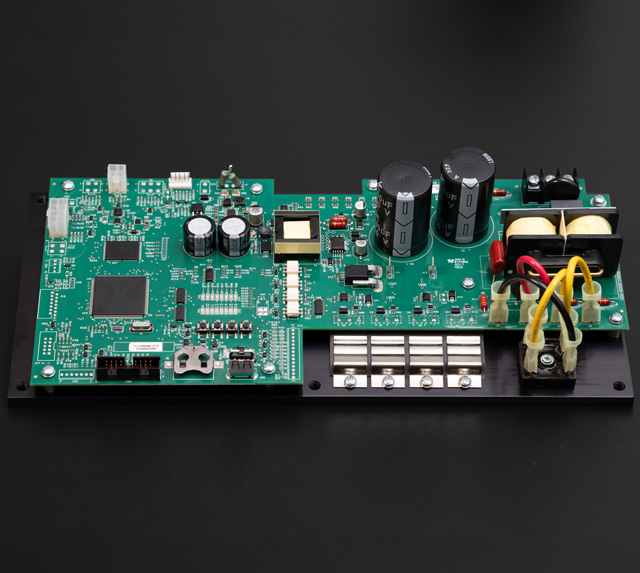

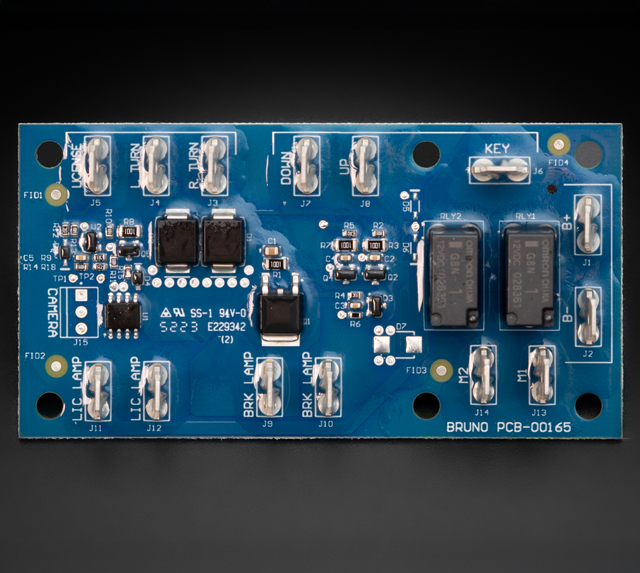

With expertise in Surface Mount Technology (SMT) PCBAs, through-hole configurations, and mechanical/chassis assembly, our capabilities span the entire product lifecycle – from initial design and development through prototyping and full-scale manufacturing.

Our state-of-the-art facility and skilled team ensure precision and quality in every project, whether it’s single or double-sided PCB assemblies.

In-House Engineering Design and Support

Cutting-edge design solutions and comprehensive support optimize projects from concept to completion, ensuring efficiency and innovation at every stage.

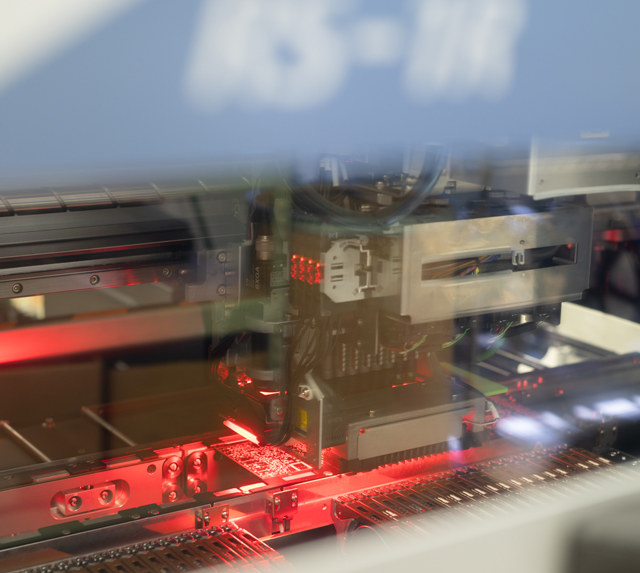

High-Speed SMT

State-of-the-art Surface Mount Technology provides high-quality, high-volume PCB assembly with unparalleled precision and efficiency, meeting the most demanding production requirements.

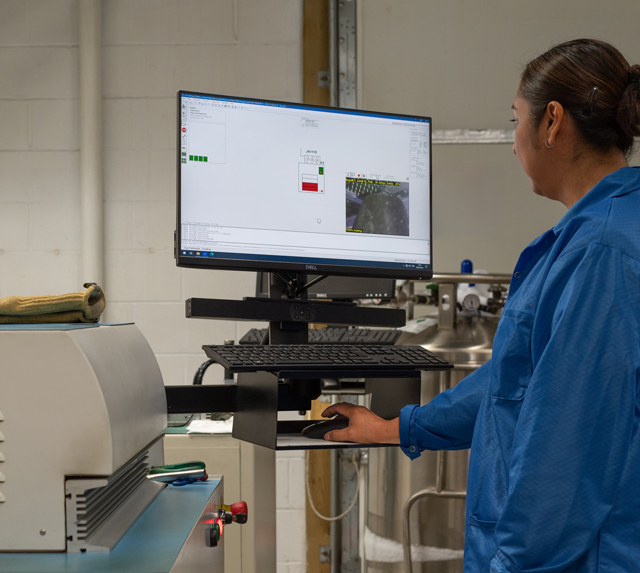

Automated Optical Inspection (AOI)

Advanced AOI systems guarantee flawless quality control, detecting even the minutest defects to ensure products meet the highest industry standards.

Expert PCBA Manufacturing

Years of experience and cutting-edge technology result in superior Printed Circuit Board Assembly solutions tailored to specific client needs and industry demands.

PCBA Through-Hole Assembly

Skilled technicians excel in through-hole assembly, providing robust and reliable connections for the most demanding applications and complex designs.

Wave Soldering

Advanced wave soldering techniques ensure consistent, high-quality connections across entire PCBs, maximizing reliability and performance.

Selective Soldering

Precision selective soldering capabilities allow for targeted, high-quality connections on complex or heat-sensitive components, preserving board integrity.

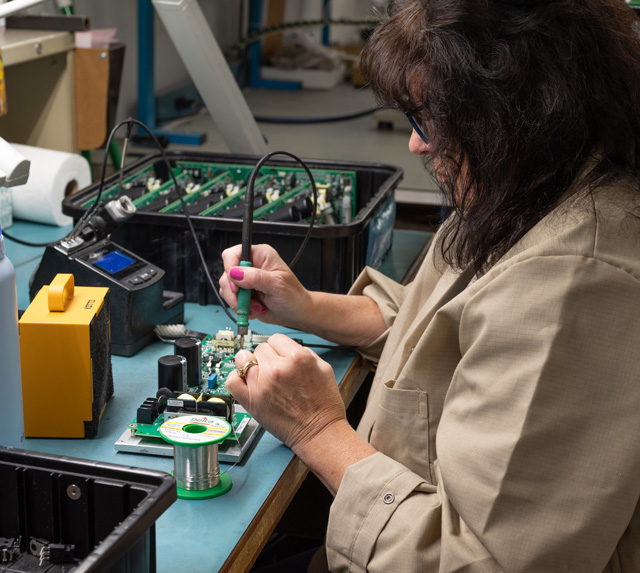

Hand Soldering

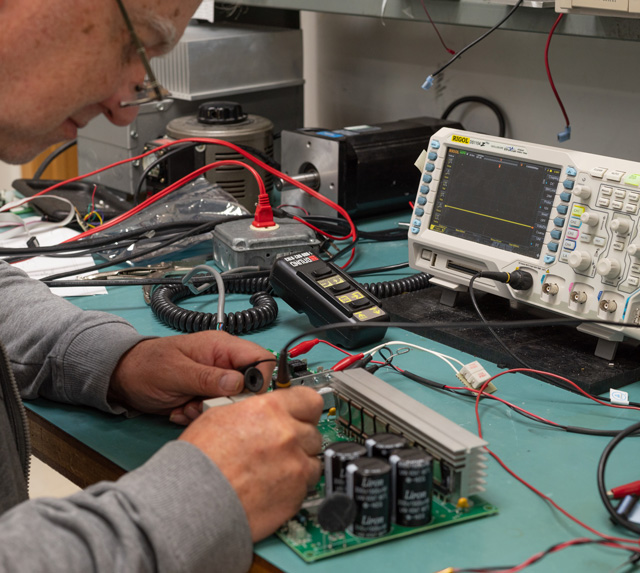

Certified technicians perform meticulous hand soldering for intricate or specialized components, ensuring the highest quality and reliability in custom projects.

Cable Wiring and Assembly

Comprehensive cable wiring and assembly services deliver custom solutions that meet exact specifications and rigorous industry standards.

CNC Machine Shop Capability

In-house CNC machining capabilities enable rapid prototyping and precision manufacturing of custom parts and enclosures, accelerating product development.

Conformal Coating

Advanced conformal coatings protect PCBs from environmental factors, enhancing durability and longevity in challenging operating conditions.

Epoxy Encapsulant Process (Potting)

Superior potting services provide unparalleled protection for electronic components, safeguarding against moisture, vibration, and thermal stress.

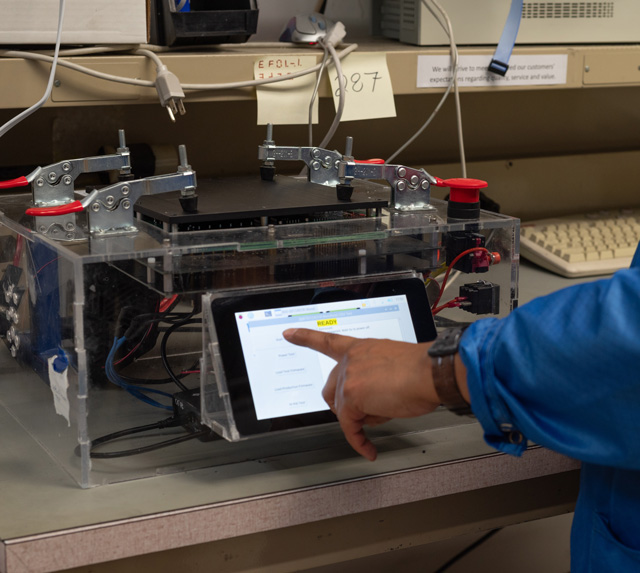

Life Cycle & HALT Testing

Rigorous life cycle and Highly Accelerated Life Testing (HALT) can ensure products meet and exceed reliability standards, identifying potential failures before they occur.

Value-Added Assembly

Streamlined value-added assembly services offer turnkey solutions that save time and resources, enhancing product quality and market readiness.

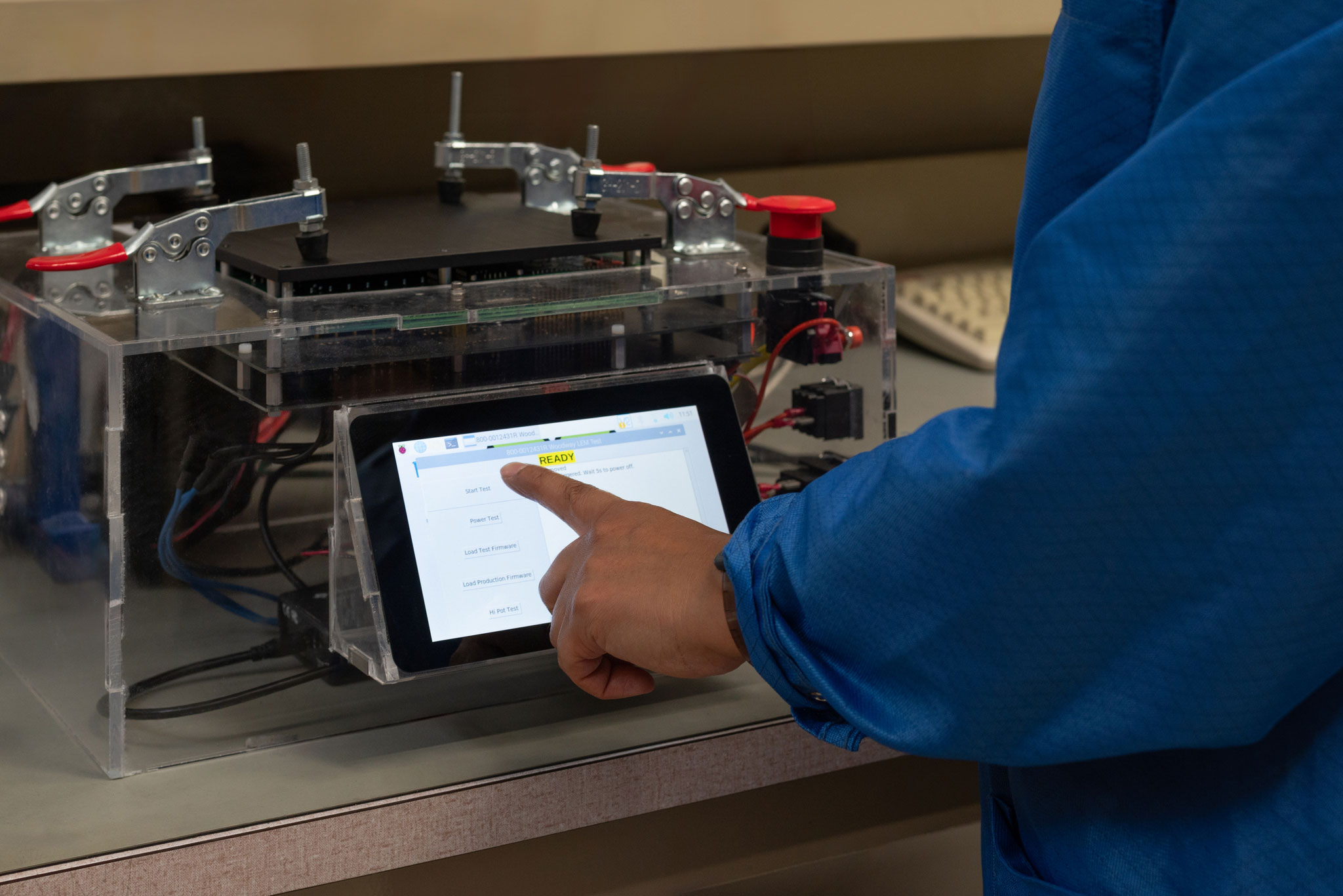

Customer Specific Test Fixtures

Custom-designed and manufactured test fixtures are tailored to unique product specifications, ensuring comprehensive and accurate testing at every production stage.

Standard Products

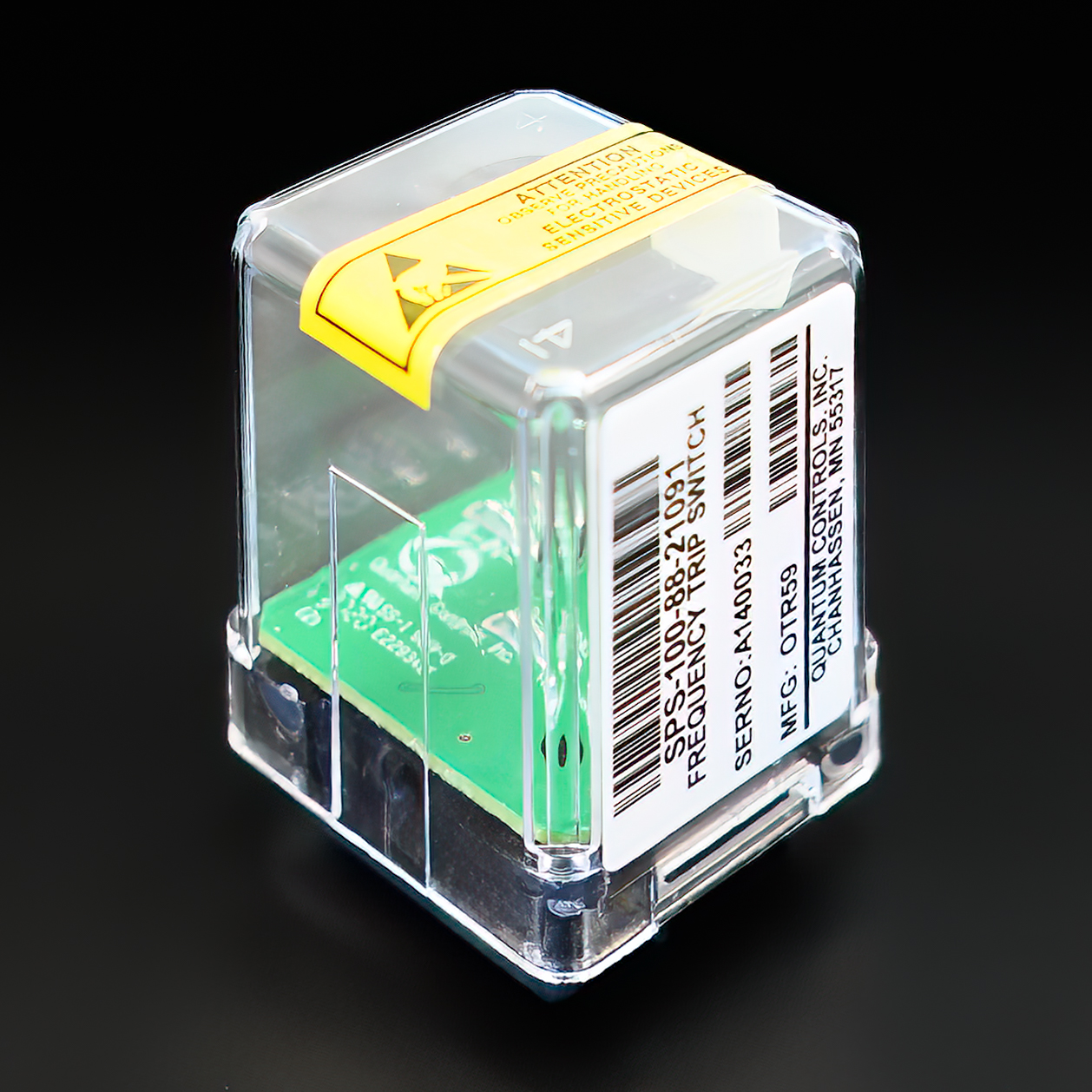

SPS-100-88-21091

This 120 / 21091 Frequency Trip Switch – This automatic starter disconnect is used on diesel-powered electric generators. In stock.

Equipment

At Quantum Controls, a diverse array of advanced equipment supports the development and manufacturing of high-quality electronic control systems. Each piece of machinery is selected for its ability to enhance precision, efficiency, and reliability throughout the production process.

This state-of-the-art equipment enables the team to execute complex designs and maintain rigorous quality standards, ensuring that every product meets the specific needs of clients across various industries.

From cutting-edge SMT machines to specialized testing and prototyping tools, the equipment utilized reflects a commitment to innovation and excellence in electronic manufacturing.

Surface Mount Technology (SMT)

Juki Model SMT Machines: High-speed, precision placement machines for efficient and accurate component mounting on PCBs

MPM Stencil Printer: Advanced stencil printer for precise solder paste application, ensuring consistent solder joints

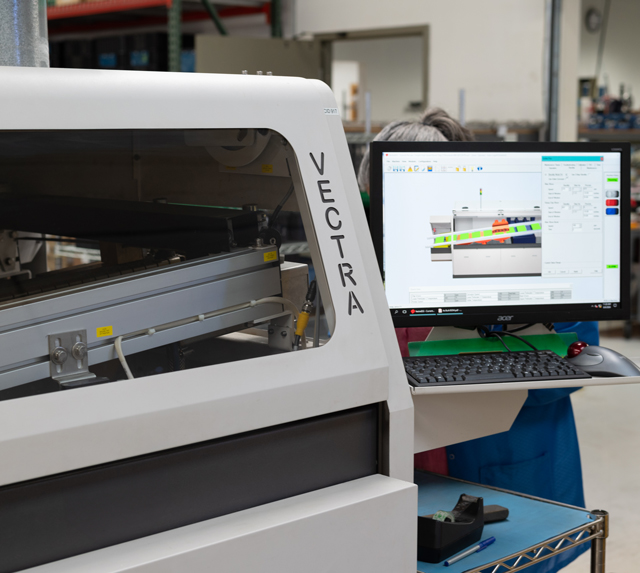

Reflow and Soldering

Heller Convection Reflow Oven: Reflow oven for controlled heating and cooling of PCB assemblies

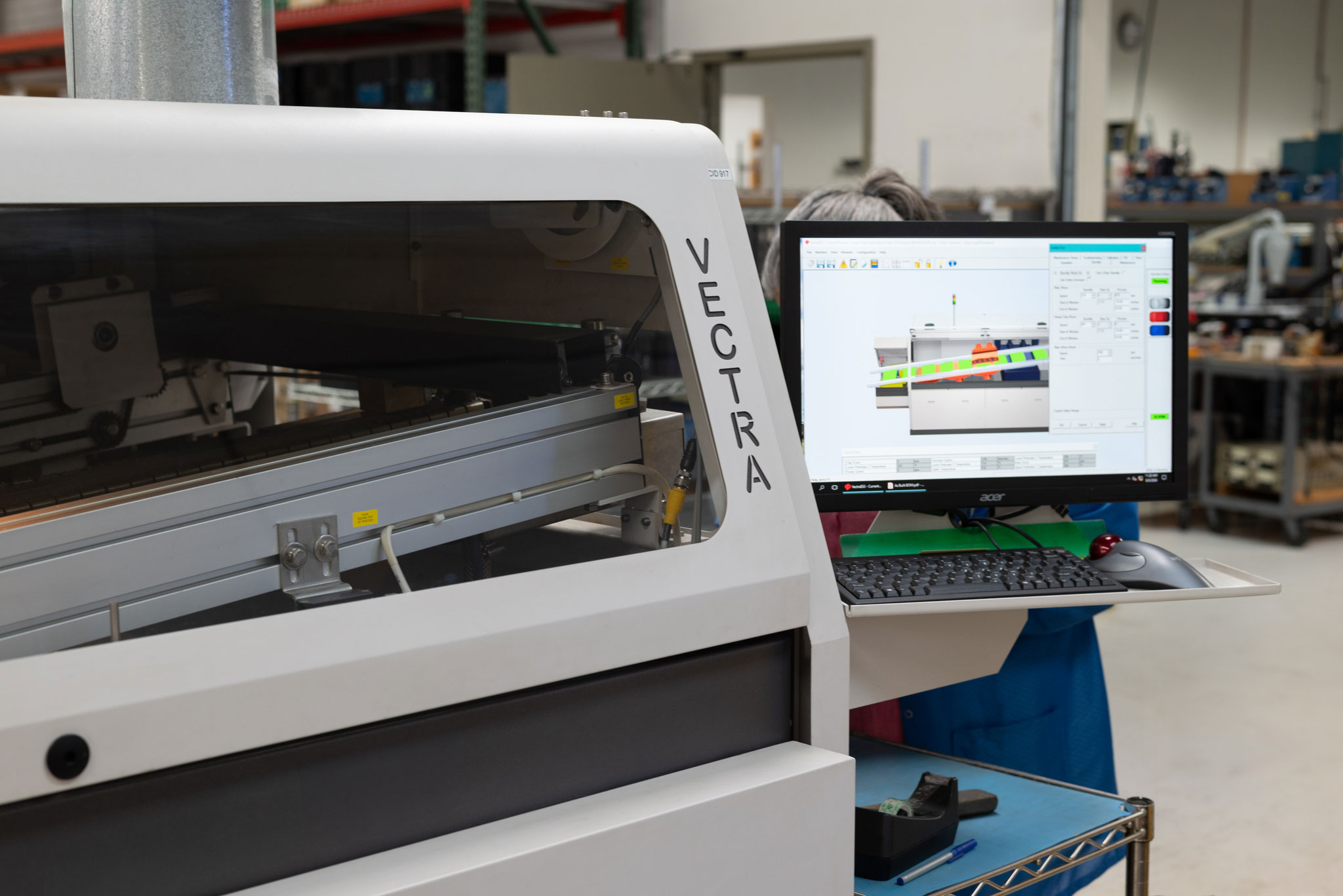

Vectra Wave Solder Machine: Automated wave soldering system for high-volume through-hole component soldering

Jade Selective Solder Machines: Precision selective soldering equipment for targeted soldering of specific components

Quality Assurance

Parmi Automated Optical Inspection (AOI) Machine: High-resolution optical inspection system for detecting defects in PCB assemblies

Specialized Assembly

Zierick Electrical Connectors & Assembly Equipment: Custom equipment for efficient and reliable electrical connector assembly

Have a specific need?

Learn how our state-of-the-art facility and skilled team can make your complex design a reality.